Temporary works experts design tower crane grillages by working with steelwork contractors

Almost every large development will need a tower crane and then a way to support it. Sometimes it is possible to connect the tower crane into the concrete supporting foundation or concrete stability covers. However, when this can’t be achieved, a bespoke tower crane grillage will need to be designed.

Tower crane grillages are designed by a temporary works expert. They work with the main contractor and the tower crane supplier to understand the complexities in order to create a safe and efficient solution.

Elland Steel manufactured the Palmerston Court grillage to EXC 3

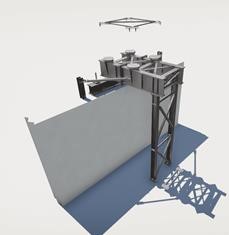

Like most projects, the main contractor decided where the tower crane needed to be positioned on their site for the best lifting access. On this tight construction site, the grillage needed to be installed partly into a concrete retaining wall, as shown below.

The tower crane details within the brief

The tower crane was 78 metres tall with up to 13,500 KNm while in service. Plus, it needed to be partly installed into the concrete retaining wall so that the loads could be transferred back down into the wall and floor slab.

Close collaboration helped to overcome challenges

Our design team worked closely with the temporary works consulting engineer to understand exactly what they wanted from the requirements laid out in their specification. It helps to interrogate the details to ensure that the best solution is agreed upon for the safest outcome.

We discussed how the forces should be transferred into the supporting sub structure on this EXC3 project. The discussions gave our design team the opportunity to resolve challenges and suggest small improvements.

Steelwork fabrication expertise helped to design the best solution

This tower crane grillage design may look simple, but it is a very involved process that requires careful planning. While consulting engineers have fantastic knowledge of what is needed, they do not have the in-depth knowledge that steelwork contractors have regarding the intricacies of fitting steel together. Only steelwork contractors can understand the complex industrial details and complications in manufacturing and erecting the steelwork.

The intricacies of the design and reiterations

The design evolved to overcome elements that originally were not feasible. The temporary works consultant engineer originally specified the primary beams as long lengths. However, with the restrictions and transports, these members had to be spliced.

4 ways this design change improved the installation process

1. Removed the need for welding on site

Welding the beams in our factory and splicing the primary beams removed the need for on-site welding. This meant that the installation works could carry on simultaneously, with no down time for welding or the testing of the finished weld.

2. Improved quality control

Welding tower crane bases on site is often tricky and time-consuming. There would have been a need for heavy prep of the elements before welding them together with no guarantee of a perfect weld in the site environment once this was complete.

3. Pre-fabricating modules saved time on site

Using butt welds and splice connections meant that we reduced the installation time on site by simplifying the process.

4. Less parts going to site

Here you can see a photo of the pre-welded steel frame going to site. Having pre-fabricated modules reduced the offloading and sorting time on site.

Tower crane installation details

The lower double web beam of the first module was fabricated with 3 location holes. This meant the assembly was easily lowered into position onto the 3 No 75mm ⌀ Macalloy tension bars that were previously cast into the concrete.

Once the first module was lowered onto the bars and tensioned to the correct torque, the second module was installed. The splice connection design meant that the second module was simply lifted into place and bolted against the first module.

Positive feedback for our tower crane grillage

We gained positive feedback from Mace for this project. When filling out the client satisfaction survey, they gave us a net promoter score of 90.

We pride ourselves on our high NPS score, which has been achieved thanks to our professional capabilities and a personal approach. We gather feedback from a range of disciplines including Quantity Surveyors, Commercial Managers, Engineers, Design Managers, Site and Project Managers. The uniformly high scores indicate consistently high standards across our commercial, technical and project teams.

More tower crane grillage examples

Our article using crane bases to improve buildability shows how we used a crane grillage to deliver a double-height extension that was an even tighter construction site for The Rowe, Whitechapel.

If you would like help with your next steelwork project, get in touch with us today.